Description

- Dual Axis Swivel Bracket w/ female couplers

- Mating Male Couplers

- Optional 30″ Mounting Post

Features

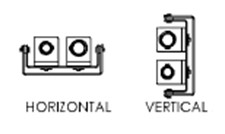

- Dual Axis Swivel Bracket Allows for Breakaway at any Angle

- Flat Face Design Eliminates Leakage at Breakaway

- Flat Face Design Eliminates Contamination From Entering Circuit Upon Connection

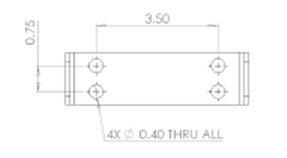

- Port Size: ½’’

- Port Type: NPT

The C-BASS system comes in a kit form consisting of an assembly with female couplers and adapters along with the mating male nipples (available in 2 sizes). An optional mounting post can also be included.

- CBASSK01 – CBASS BREAKAWAY ASSEMBLY KIT

- Breakaway Bracket Assembly with Female Couplers

- Mating Male Couplers

- 90 Degree Adapters for Female Couplers

- CBASSK02 – CBASS BREAKAWAY ASSEMBLY KIT WITH MOUNTING POST

- Breakaway Bracket Assembly with Female Couplers

- Mating Male Couplers

- 90 Degree Adapters for Female Couplers

- 30” High Mounting Post *

- CBASSPOST30

- 30” High Mounting Post *

* In the event that the C-BASS unit is not mounted directly on the compactor or an adjacent fixed structure, mounting post is recommended. Post is available separately for large fleet orders. Contact us for more information.

olution

olution